In the ever-evolving sectors of aeronautics and naval engineering, precision, durability, and compliance with stringent industry standards are paramount. Systana Laser Engraving leverages cutting-edge laser engraving technology to meet these demands, offering unparalleled benefits to clients in these fields since more than 15 years.

The Benefits of Laser Engraving in Aeronautics and Naval Industries

Laser engraving provides a host of advantages for industrials and ship builders, making it an indispensable tool in the aeronautic and naval sectors. Here’s why:

Precision and Accuracy: Laser engraving ensures high precision, reducing the risk of errors, vital for creating intricate and accurate markings on components.

Durability: The marks created by laser engraving on our products are resistant to harsh environmental conditions, such as salted water, ensuring longevity and readability.

Compliance with Standards: Laser engraving helps in meeting industry standards and regulations, as per your specs, crucial for safety and operational efficiency final results.

Ensuring Compliance with Industry Standards

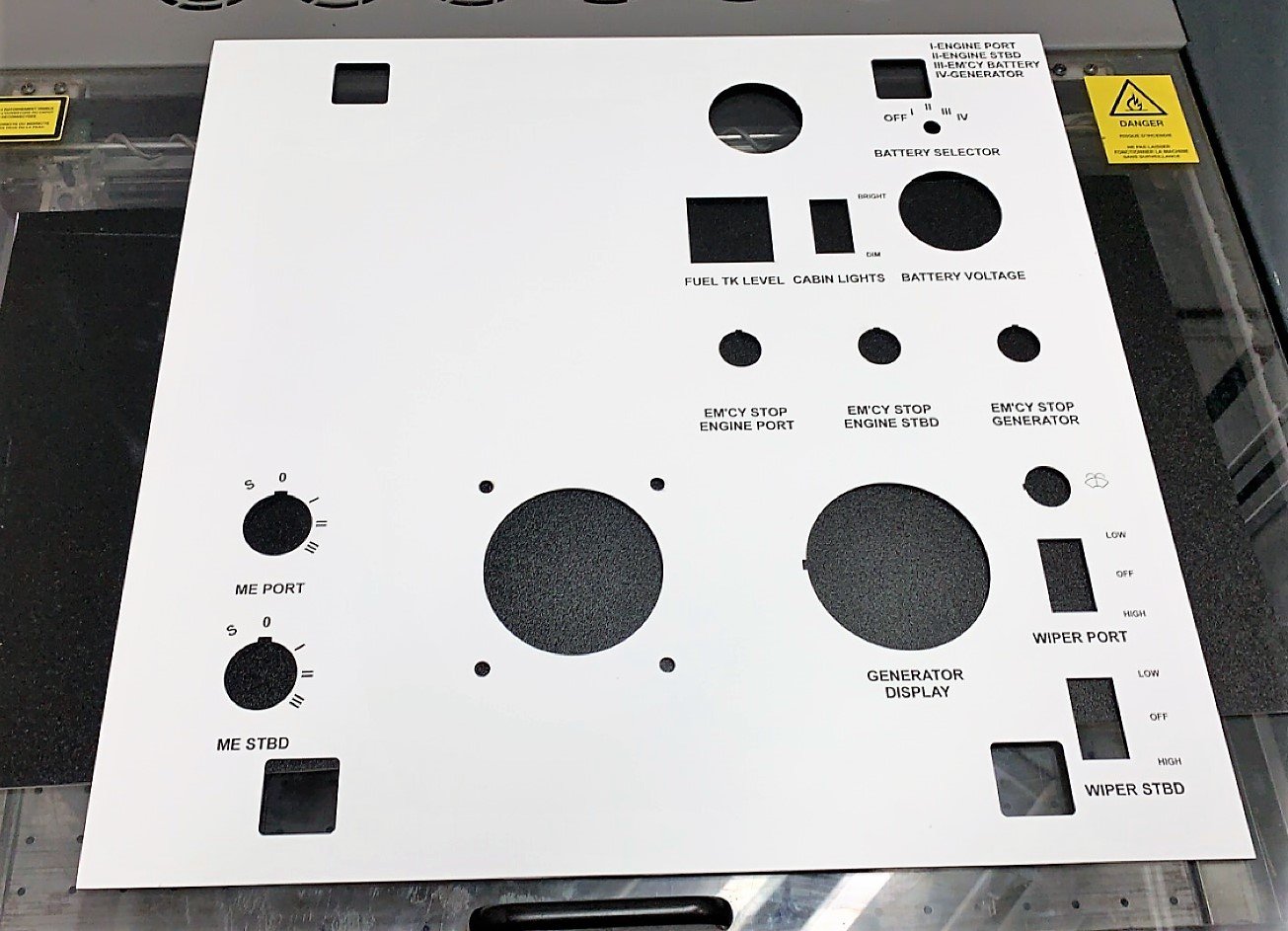

In both aeronautics and naval industries, adherence to stringent standards is crucial. Laser engraving facilitates compliance by providing permanent, readable, and precise markings that meet regulatory requirements ask by your engineers. This includes everything from serial numbers and part numbers, buttons and control panels, to safety instructions and certification marks.

Common Materials Engraved with Laser Technology

Systana Gravure Laser works with a variety of materials commonly used in aeronautics and naval industries, including:

Metals: Stainless steel, aluminum and Durablack.

Plastics: Rowmark High-performance Plastics used in various components.

Enhancing Durability and Readability

One of the standout features of laser engraving is its ability to produce durable and highly readable markings. These markings withstand extreme temperatures, salted water, humidity, corrosion, and wear, ensuring they remain legible throughout the component’s lifespan.

Specific Applications in Aeronautic and Naval Fields

Laser engraving is used in numerous applications within these sectors, such as:

Component Identification: Marking serial numbers, part numbers, and barcodes for tracking and inventory management.

Safety Instructions: Engraving essential safety guidelines and operational instructions directly onto parts.

Compliance Labels: Creating labels that meet regulatory standards for safety and quality assurance.

Why Choose Systana Gravure Laser?

At Systana Gravure Laser, we understand the unique challenges faced by the aeronautic and naval industries. Our advanced laser engraving solutions are tailored to meet these needs, ensuring precision, durability, and compliance. Trust us to provide top-tier engraving services that enhance the safety, efficiency, and longevity of your components.

Ready to elevate your marking and engraving processes? Contact Systana Gravure Laser today to learn more about our specialized services for the aeronautic and naval industries. 📞✉️