LASER MARKING ON STAINLESS STEEL AND ALUMINUM

Expertise and Versatility: Specializing in Stainless Engraving with laser for over a decade, catering to various industries like marine, military and machinery.

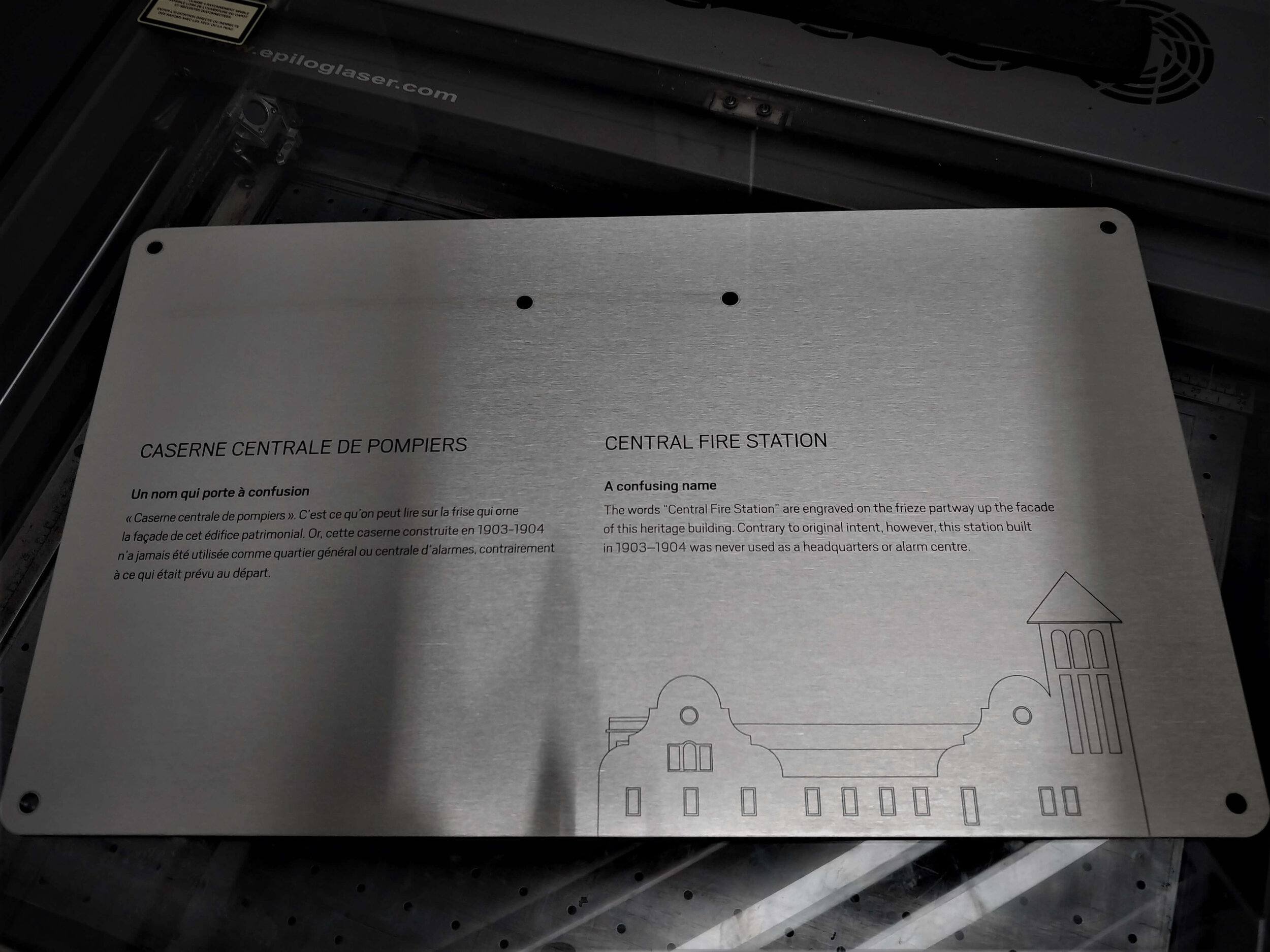

Technology: Utilizing CO2 and fiber laser machines for high-quality results on metals, including options for adding logos or text for branding and identification.

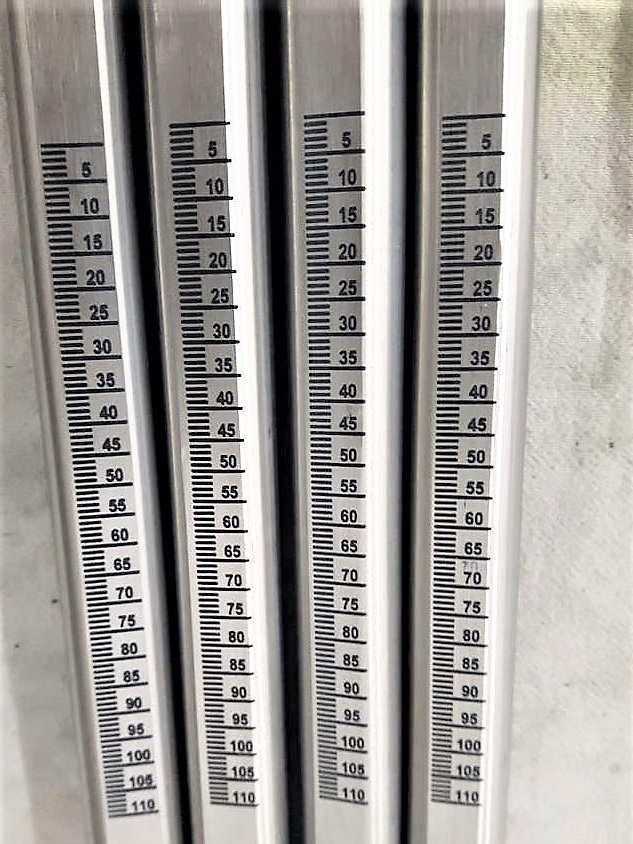

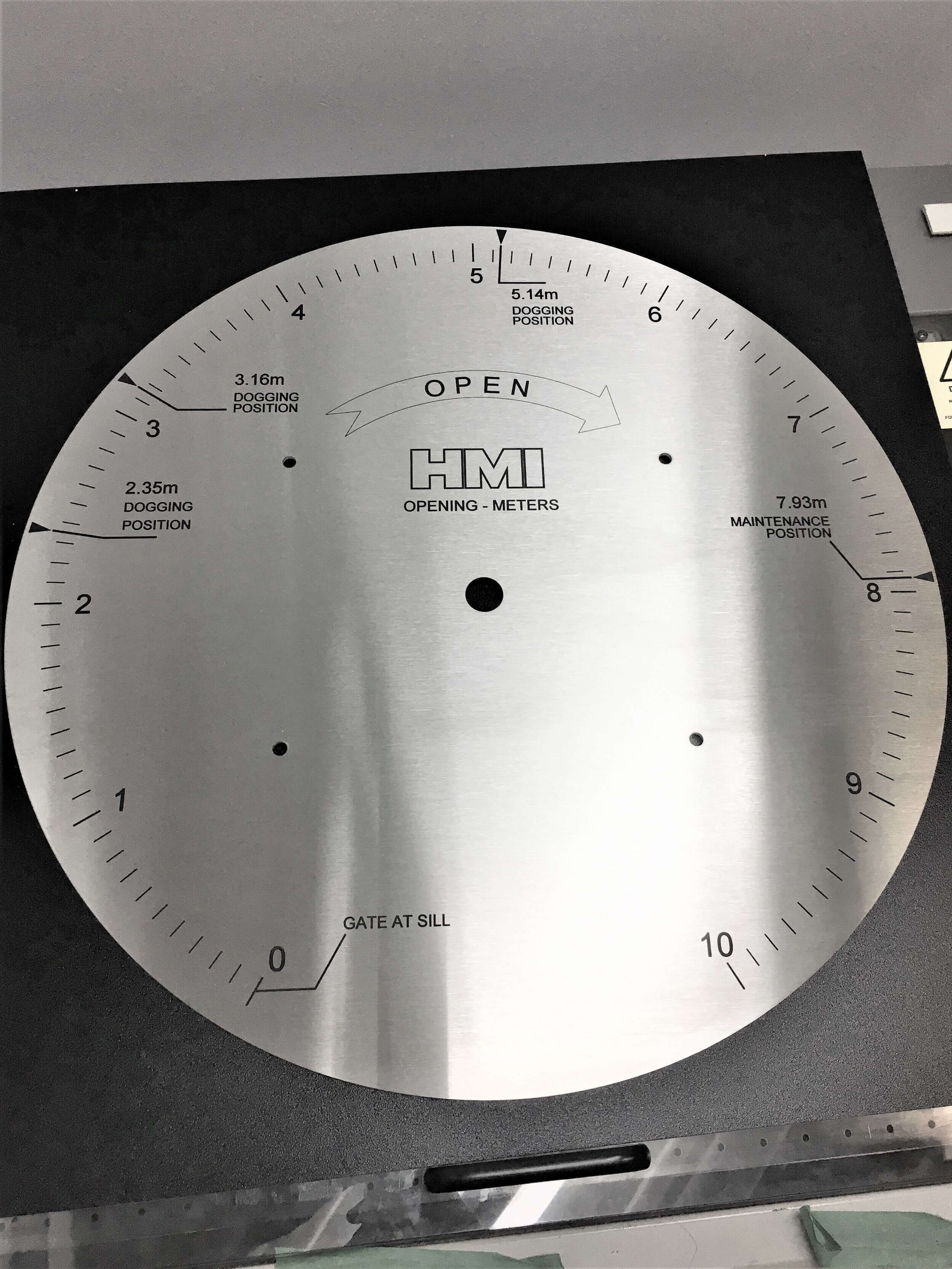

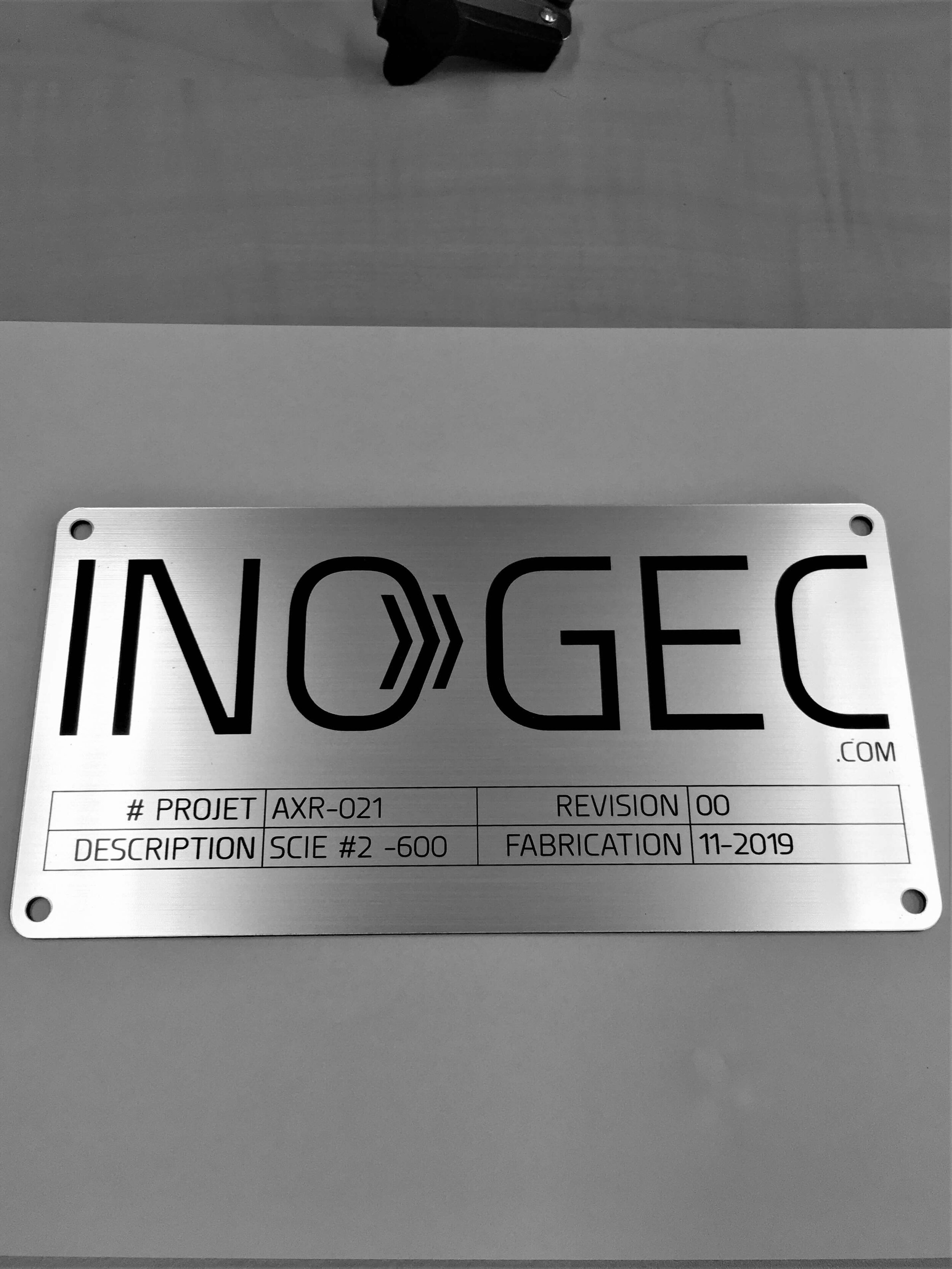

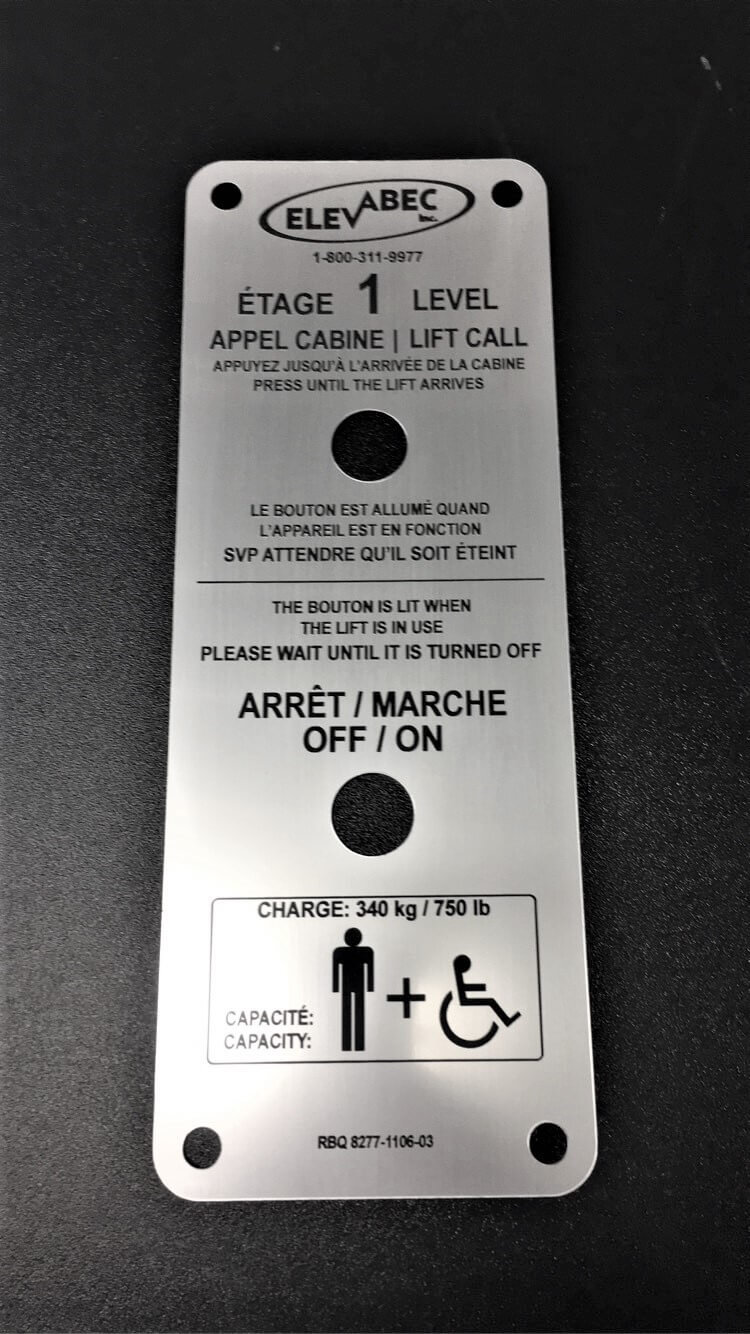

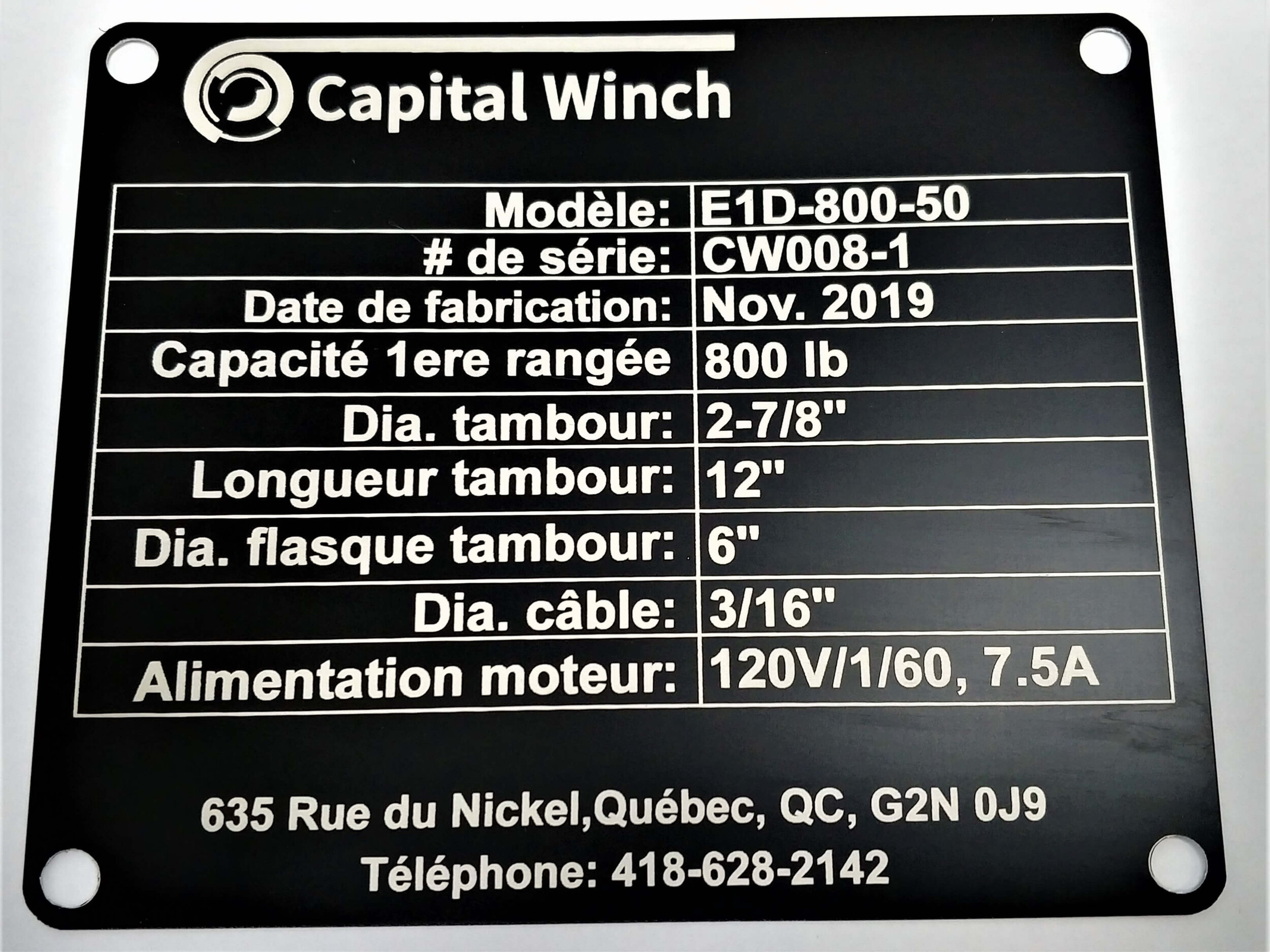

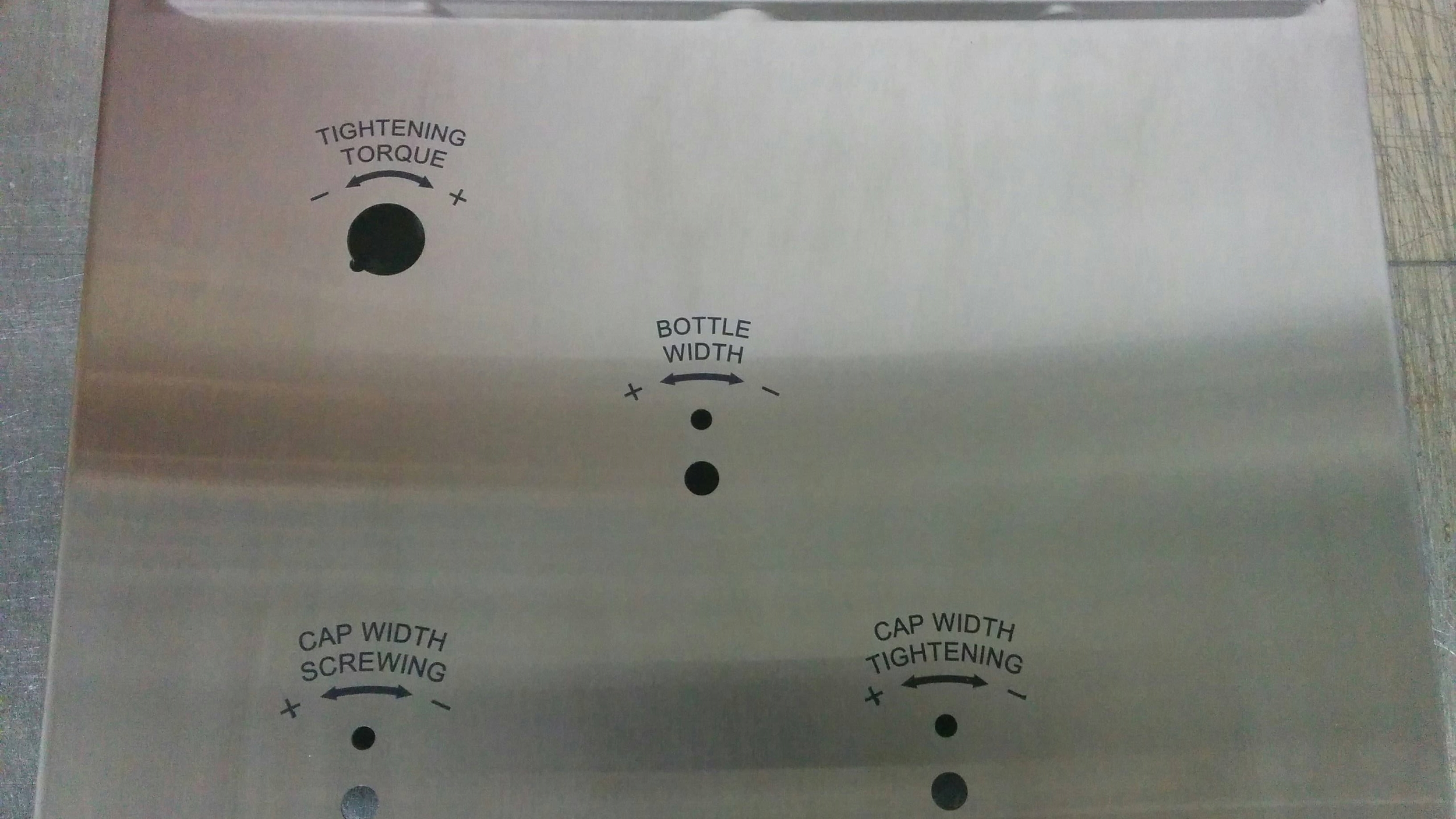

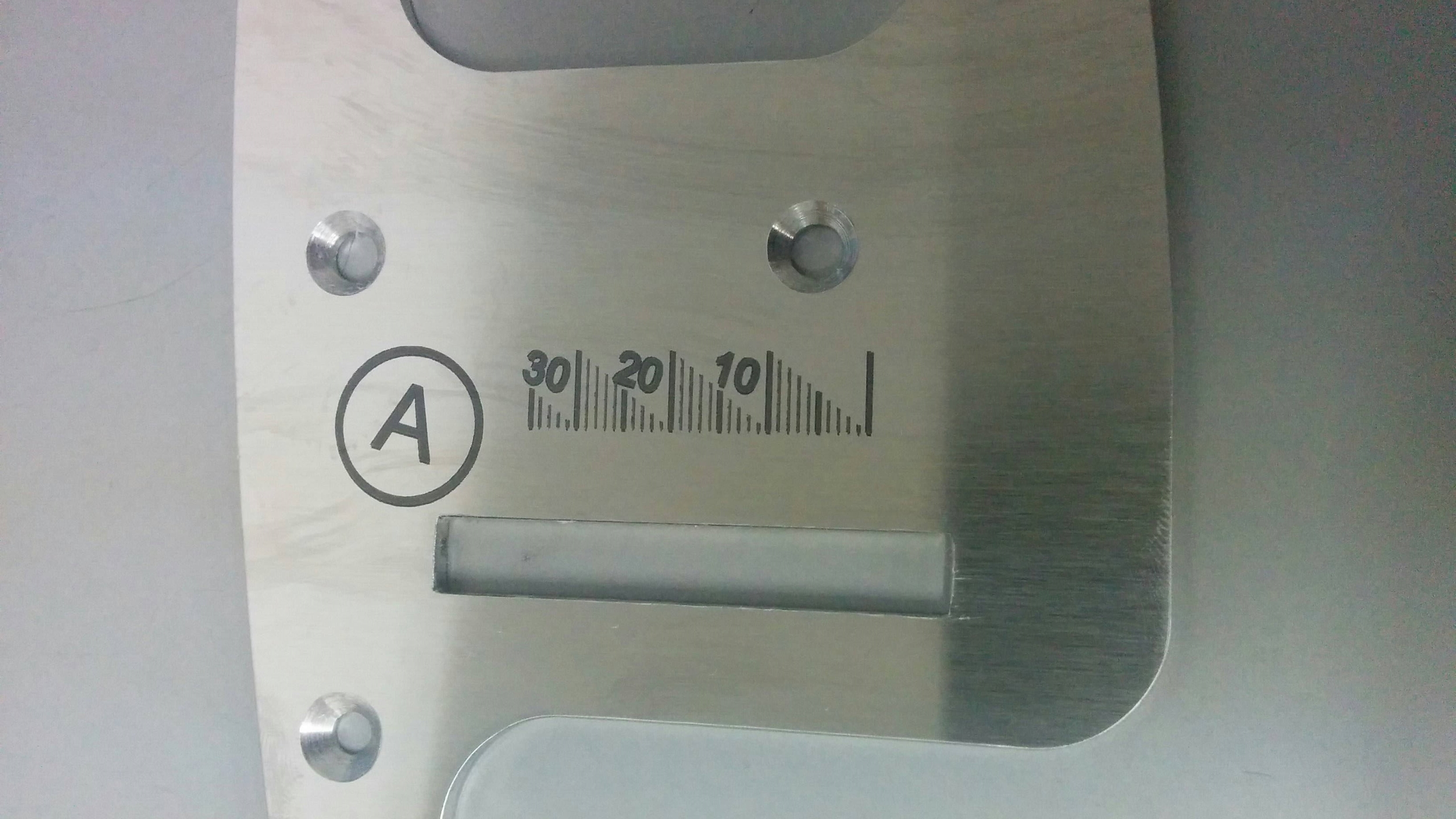

Wide Application Range: Serving Montreal, Quebec City, Ottawa, and beyond, with solutions for precision rulers, control panels, identification plates, barcodes, and QR codes, Stainless Engraving.

Customization and Quick Turnaround: Offering personalized solutions and efficient production timelines.

See how Systana is revolutionizing laser marking for stainless steel and aluminum machinery! Our video, "Sherbrooke Commercial Metal Laser Marking," showcases our precise and permanent engraving process. Perfect for industrial applications.

We have been master of laser marking on metal for over a decade.

When marking metals (also called etching) such as stainless steel, the laser fuses another product based on ceramic powder on the material, which leaves a permanent black mark on it. . This allows us to make lettering numbering and logo printing.

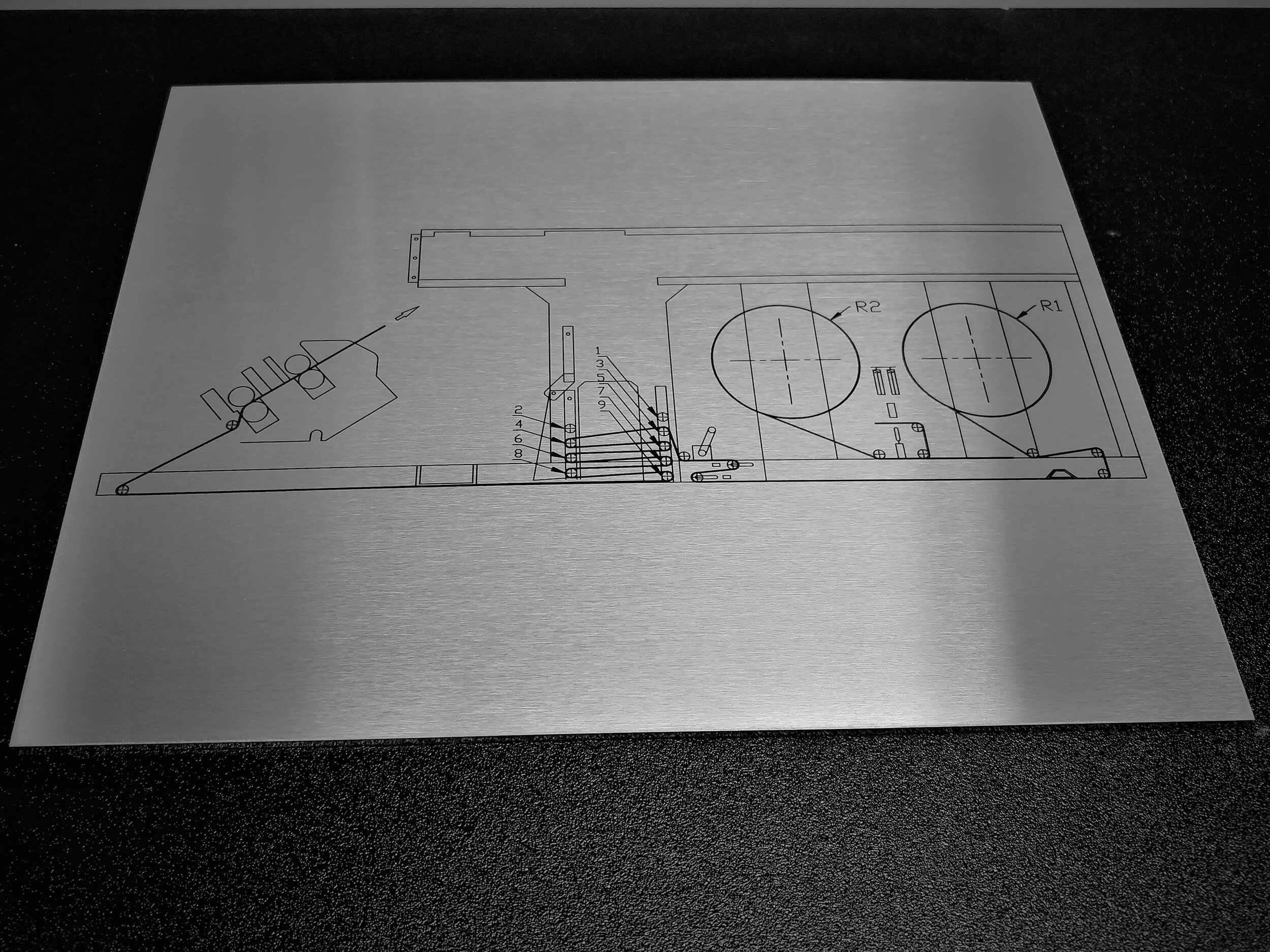

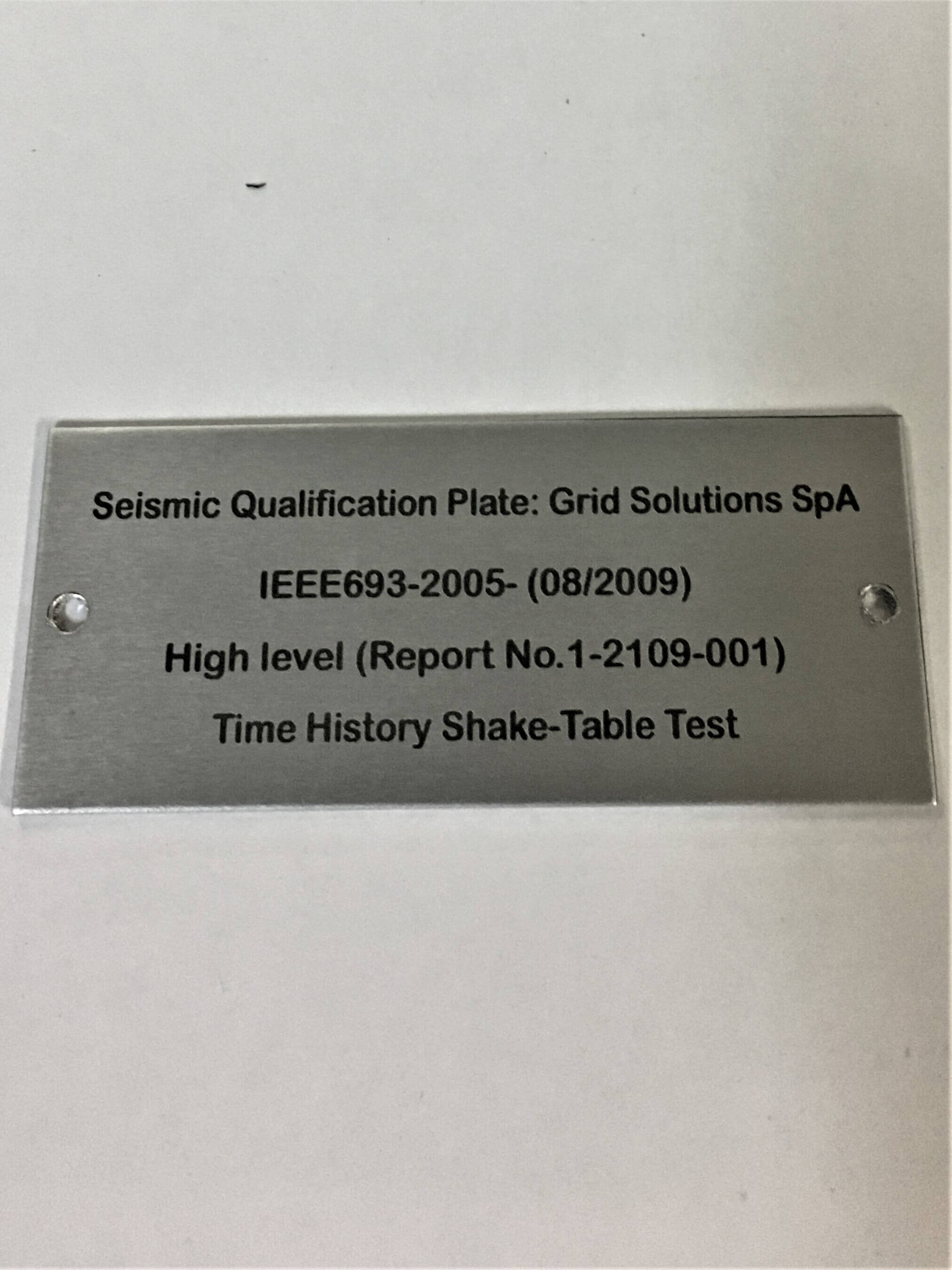

As an example of what we are currently producing with Stainless Engraving for our laser marking customers: stainless steel precision ruler, marine and other industries control panels, identifications plates, bar codes, QR codes and identification for plate elevator control, machinery and equipment.

Metal engraving is an art that we have mastered since 2007. We are the largest engraved plate manufacturer in Quebec. Our CO2 laser engraving machines are very efficient and our team is trained to provide the quality of product that makes the name of Systana Laser Engraving. See examples of all the products we make in our Products Albums page

Let us engrave your business logo or text on to metal products for an added level of protection and branding. Our fibre laser machines and CO2 laser are the best in the business, and our team of experts will make sure your product looks great!

Whether you are based in Montreal, Quebec City, Ottawa or in any other region, we can do your Stainless Engraving or Laser etching production. Do not hesitate to ask our experts for information about your laser marking projects.

Customize Your Products with Laser Marking

With our services, you can easily add an identification mark to metal items. We offer a wide range of laser engraving and marking options, so you can find the perfect solution for your needs.

Many materials are good candidates for laser engraving, whether for wood laser engraving, laser engraving on plastic or glass. But in the case of some, more often in metals (aluminum and stainless steel, because of their hardness, we can not pass through them and that is where the laser marking comes in.

Laser marking is a technique that differs a little from laser engraving since it does not give exactly the same result. The main difference between engraving and marking is that the process adds a layer when writing instead of digging stainless steel or aluminum as laser engraving does. The laser marking is permanent, durable and very esthetic.

• Get your custom engraved or marked metal products

• Increase brand visibility with professional engraving and marking

• Trust us to get the job done right - we've been doing it for over 15 years.

Laser Marking on Metal

Laser marking on stainless steel

Questions and answers about Laser Marking:

How does laser marking on aluminum works?

Marking on aluminum works in three ways. 1- We have in stock aluminum plates which are specifically designed for laser engraving, this is the simplest solutions. 2- Anodized aluminum is etched directly with the laser, due to its chemical process which reacts with the heat of the laser. 3- For a piece of virgin aluminum, we use Cermark (ceramic powder in liquid form which fuses with aluminum during the passage of the laser) in order to leave a black finish on the surface. In all cases, our experts will look at the best marking solution on your piece of aluminum to be marked. If you are looking for our military grade Durablack Aluminum please click here: Durablack Anodized Aluminum

Is the laser engraving on stainless steel permanent?

YES! It is one of the most durable ways on the market to use the precision of laser engraving to achieve permanent marking. There are two ways to mark this metal. With a CO2 engraver, we apply Cermark ceramic powder to the stainless steel which, when passed through the laser, fuses with the metal. With our new fiber engraver, the marking does not require powder. You will always have a lasting, clean and precise marking!

What types of marking can I get done with Systana Laser Engraving on stainless steel or aluminum?

Laser engraving is a process of using a high powered laser to etch an image or design onto a material. It is a popular choice for engraving because it is precise and can be done quickly. There are many different materials that can be engraved using this method, including stainless steel, aluminum, wood and even glass. Among the most popular things to engrave are logos, coordinates, company names, and any vectorized drawings. Serial numbers, QR codes, and barcodes are also commonly engraved.

How long will it take to have my order processed and marked if I chose stainless steel as the material?

Assuming you're talking about laser engraving on stainless steel, the answer to your question largely depends on the item to be engraved. For example, if you're engraving a piece of stainless steel, we'll first have to order the metal and have it cut before you we begin the engraving process. This usually takes between 8 and 10 days. Once the material is at the production facility, the engraving process can begin. The time it takes to complete the engraving will depend on the size and complexity of the design, and, of course, with the quantity of plaque ordered. However, most engravings can be completed within a few hours. The size of the engraving also affects the speed. A small, simple image can be engraved quickly, while a larger, more detailed image will take longer. Usually, once we have the metal in hand, you can pretend to receive your order within 3 to 5 days.

How Much Will My Laser Marking Order Cost?

The cost of your engraving order will depend on a few factors, including the size and complexity of the design, the number of items being engraved, and the material being engraved. Engraving is a very fast process, so even complex images can be engraved in a matter of minutes. However, the exact time will depend on the factors mentioned above. Engraving times are typically quite short, so the overall cost of your order should be relatively low. Please click here and describe your project, we will be happy to send you a quote.

Are there any discounts available for large orders of SS or aluminum orders with Systana Laser Engraving?

When you are looking at ordering engraved metal plates, you may be wondering if there are any discounts available for large orders. The answer is yes! The more you order, the less each unit will cost you. This is because when we order the metal, there is a minimum order fee. Then, you must add the transport cost from the metal provider to our production facility. However, it is almost the same cost of transport for one plaque and for 10. Therefore, the more you order at the same time, the cheaper you will pay. At our company, we generally make good discounts on orders over 100 units. This allows you to save money on your purchase while still getting high-quality engraved metal plates. So, if you are looking for a way to save money on your order, consider ordering a larger quantity. You can find more information about this by contacting us.

Can I get my order laser Marked and shipped to me quickly?

When you place an order with us, you can be assured that we will provide you with the highest quality product possible. We understand the importance of getting your order shipped to you quickly, and we are committed to providing you with the best possible service. In most cases, it takes our team 3 to five days to complete an order, once the final drawing for production is approved. Then, with a courier service, you will receive your order the next day!

How do I get a quotation for my stainless steel or aluminum marking project?

Simply click here to reach us, describe your project and we will answer you within 24 hr! You can also receive a free quote for your custom order by clicking on the Get a Quote button.

What are the pros and cons between the stainless steel and the aluminum laser marking, if I have to choose?

Aluminum

· Aluminum is a softer metal, which means it is more vulnerable to scratches and scuffs.

· Aluminum is lighter than stainless steel, which can be an advantage if you are looking to save on shipping costs.

· Aluminum does not rust, but it will oxidize over time.

· Aluminum is less expensive than stainless steel.

Stainless Steel

· Stainless steel is a harder metal, making it more resistant to scratches and scuffs.

· Stainless steel is heavier than aluminum, which can be a disadvantage if you are looking to save on shipping costs.

· Stainless steel will not rust or oxidize over time.

· Stainless steel is more expensive than aluminum.

WHICH LASER MARKING TECHNIQUE TO USE: LASER MARKING OR LASER ETCHING?

When it comes to laser technology, many people are unsure of the difference between laser marking and laser etching. And more importantly, which one is right for you. At Systana Laser Engraving, we specialize in both laser marking and laser etching to help you achieve the perfect results for your business and your identification process. The main difference between laser etching and laser marking is that etching melts the micro surface to create a little raised marks, whereas marking removes a small amount of material to create shallow marks. Both processes use high heat to create permanent markings on metal surfaces with an industrial laser machine. Both processes are heavily used for part traceability and industrial laser identification. Let’s dive into each process to see which is best, for which application. The Laser Etching Process When etching is performed, the laser heats and distorts the micro surface of the material. By doing so, the laser etched surface expands and creates a texture. Laser etching creates black and white marks and is the most efficient process to permanently mark most types of materials. Etching is faster than marking because it requires less energy from the laser beam. You may need laser etching if:

• Your part is made of any metal, except stainless steel.

• You want the fastest laser process.

• You want a cost-effective laser that requires less laser power.

• You need to integrate laser marking before non-abrasive treatments, including powder coating, e-coating, and heat treating.

The Laser Marking Process

Through the marking method, the laser vaporizes a thin layer of the material to create a tracking code. This is done by sending a highly localized laser pulse onto your part. Instead of creating a micro-surface that is raised above the material, laser marking digs into the material.

You may need laser marking if:

• Your part is made of steel or aluminum

• You want marks with maximum durability.

• You need to integrate laser marking before abrasive treatments, including sandblasting.

Why Do You Need Laser Marking & Laser Etching?

There are many reasons why laser marking and etching are becoming increasingly popular in industrial settings. One of the biggest advantages of using laser technology for marking and etching is the cost savings over traditional methods. For example, dot peening, inkjet printing and printed labels all require regular maintenance and have consumable costs that can add up over time. Another major advantage of laser marking and etching is their reliability and consistency. Traditional marking methods can produce inconsistent results due to factors such as wear and tear on equipment, human error and environmental factors. With laser technology, the marks produced are always consistent and precise, which is especially important in industries where traceability is crucial. Additionally, laser marking and etching are highly versatile and can be used on a wide variety of materials, including metals, plastics, and ceramics. They also offer a wide range of capabilities, such as the ability to create high-resolution marks with detailed information and graphics. Laser marking and etching offer many advantages over traditional marking methods, including cost savings, reliability, consistency, and versatility. This makes them an ideal choice for many industrial applications, especially those where traceability and precision are important.

Industrial Applications and Sectors That Use Laser Marking and Etching Technology

Automotive Industry:

The automotive industry is one of the main users of laser marking technology and etching technology. Car manufacturers have long required traceability solutions for their suppliers, and they were early adopters of the data matrix code as a way to uniquely identify parts going into the final assembly. The parts are scanned at crucial steps throughout the value chain to ensure conformity and enforce accountability. Nowadays, they require that laser part identification be performed as early as possible. For example, laser marking is used to permanently mark engine blocks with serial numbers and other important information for traceability. This helps manufacturers keep track of each engine block throughout the production process and ensure that the right engine is put into the right car. Additionally, laser etching technology is used to mark various car parts, such as wheels and brake discs, with the manufacturer’s logo and other important information. This helps to brand the parts and make them easily identifiable, which is important for both the manufacturer and the customer.

Primary Metals Industry:

The primary metal industry, including smelters, dies casters, hot and cold roll plants, and extruders, also heavily rely on laser marking technology and etching technology. They found out that the data they gathered from their internal traceability program helped them optimize their processes. Others used laser coding to manufacture products that meet strict environmental standards, differentiating themselves from their competitors. For example, laser marking is used to mark metal sheets with important information such as thickness, alloy composition, and serial numbers. This information is important for traceability and for ensuring that the right metal sheets are used in the right products. Additionally, laser etching technology is used to mark metal parts such as gears, valves, and other mechanical parts with important information such as part numbers, serial numbers and other information for traceability.

Medical Device Manufacturers in the medical device industry:

The government has established strict regulations that require the identification of medical devices. It requires that most medical devices be identified with unique identifiers. Laser marking technology and etching technology is the most common method for meeting these requirements. For example, laser marking is used to mark surgical instruments with important information such as the manufacturer’s name, the instrument’s name, and serial number. This information is important for traceability and ensuring that the right instruments are used in the right procedures. Additionally, laser etching technology is used to mark implantable devices such as pacemakers and artificial joints with important information such as the device’s serial number, the manufacturer’s name, and other information for traceability.

Manufacturer of Machine, Tools and Automation Industry:

The manufacturer of machines, tools, and automation industry also heavily rely on laser marking technology and etching technology. They use it to mark their machines, tools, and automation equipment with important information such as the manufacturer’s name, model number, and serial number. This information is important for traceability solutions and ensuring that the right machines, tools, and automation equipment are used in the right applications. Additionally, laser etching technology is used to mark various machines, tools and automation parts, such as gears, valves, and other mechanical parts with important information such as part numbers, serial numbers and other information for traceability. This helps the manufacturer to keep track of their products throughout their life cycle and to ensure that their customers are provided with the best quality products.